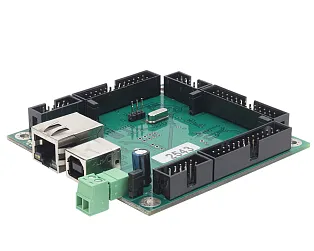

Ethernet controller PLCM-E1b is designed for connection to the CNC software Pumotix. Controller...

-

Hardware-software solution to control a CNC machine. Innovative Russian development including software and a PLCM motion controller.

*buying a PLCM motion controller you get basic functions of the software.

-

- advanced service of holographic control programs;

- adaptive interface and sensor screens support;

- program control visualization in mode of 3Dsurface;

- external control devices support (pendants and gamepads);

- simulation mode for testing program control execution;

- two languages interface (RU/EN);

- unlimited application period of the ordered options.

-

PACKAGE OFFEROptimum set of program modules for CNC machines.

Options

In consequence of the flexible licensing system, PUMOTIX software and hardware complex users can choose and purchase only those options that are necessary for working on a particular CNC machine. As a matter of convenience, options are divided into several blocks.

The feature allows to use "Probing" tab from PUMOTIX main window interface.

The feature allows you to use a stepper or servo motor with STEP / DIR control as a spindle. This mode allows precise setting of the speed and acceleration profile of the spindle drive directly from the PUMOTIX software. It's recommended to use this option in conjunction with spindle unit based on stepper or servo motors.

Attention!

Attention!

Attention!

Attention!

The feature allows to control a active rollgang. It can be used when cutting heavy pipes using rotary axis.

Attention!Postprocessor for 5-axis continuous milling operations. Used for the preparation of milling NC programs for machines with the XYZABC axis names (various types of 5-axis cnc machine configurations: table-table, head-head, or head-table). Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

Postprocessor for 4-axis continuous milling operations. Used for the preparation of milling NC programs for machines with the XYZA axis names (the A-axis is directed along the X-axis) or XYZA (the A-axis is directed along the Y-axis) or XYZB (the B-axis is directed along the Y-axis). Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

Postprocessor for 4-axis continuous milling operations. Used for the preparation of milling NC programs for machines with the XYZA axis names (the A-axis is directed along the X-axis) or XYZA (the A-axis is directed along the Y-axis). Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

Postprocessor for milling machine with rotary axis A. The coordinates of the rotary axis are prepared by unrapping along the X or Y axis. Used for the preparation of milling NC programs for 4-axis machines with the XYZ axis names. Tool change (M6) is supported.

Postprocessor for CNC routers. Used for the preparation of milling NC programs for 3-axis machines with the XYZ axis names. Tool change (M6) is supported.

Postprocessor for CNC routers. Used for the preparation of milling NC programs for 3-axis machines with the XYZ axis names. Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

Postprocessor for plasma cutting machines. Used for the preparation of NC programs for 3-axis machines with the XYZ axis names.

Postprocessor for CNC routers. Used for the preparation of milling NC programs for 3-axis machines with the XYZ axis names. Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

Postprocessor for 4-axis continuous milling operations. Used for the preparation of milling NC programs for machines with the XYZA axis names (the A-axis is directed along the X-axis) or XYZA (the A-axis is directed along the Y-axis). Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

Postprocessor for 4-axis continuous milling operations. Used for the preparation of milling NC programs for machines with the XYZA axis names (the A-axis is directed along the X-axis) or XYZA (the A-axis is directed along the Y-axis) or XYZB (the B-axis is directed along the Y-axis). Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

Postprocessor for 5-axis continuous milling operations. Used for the preparation of milling NC programs for machines with the XYZABC axis names (various types of 5-axis cnc machine configurations: table-table, head-head, or head-table). Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

Postprocessor for CNC routers. Used for the preparation of milling NC programs for 3-axis machines with the XYZ axis names. Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

Postprocessor for CNC routers. Used for the preparation of milling NC programs for 3-axis machines with the XYZ axis names. Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

Postprocessor for CNC routers. Used for the preparation of milling NC programs for 3-axis machines with the XYZ axis names. Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

Postprocessor for CNC routers. Used for the preparation of milling NC programs for 3-axis machines with the XYZ axis names. Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

Postprocessor for milling machine with rotary axis A. The coordinates of the rotary axis are prepared by unrapping along the X or Y axis. Used for the preparation of milling NC programs for 4-axis machines with the XYZ axis names. Tool change (M6) is supported.

Postprocessor for CNC routers. Used for the preparation of milling NC programs for 3-axis machines with the XYZ axis names. Tool change (M6) is supported. Coolant (M7/M8/M9) is supported.

A custom postprocessor development service is available. Software engineers will build a post processor for any machine configuration and CAM system.

Package options

-

MILLING, ROTARY AXISOne additional motorRotary axis A in index modeArticle ER-0001310592 $46 $46 $add TO cart IN cart

MILLING, ROTARY AXISOne additional motorRotary axis A in index modeArticle ER-0001310592 $46 $46 $add TO cart IN cart -

5-AXIS (INDEX)Unlimited motorsRotary axis A in index modeMulti-axis index processingArticle ER-00013106185 $92 $92 $add TO cart IN cart

5-AXIS (INDEX)Unlimited motorsRotary axis A in index modeMulti-axis index processingArticle ER-00013106185 $92 $92 $add TO cart IN cart -

5-AXIS (CONT)Unlimited motorsRotary axis A in index modeMulti-axis index processingMulti-axis continuous machiningArticle ER-00013107246 $123 $123 $add TO cart IN cart

5-AXIS (CONT)Unlimited motorsRotary axis A in index modeMulti-axis index processingMulti-axis continuous machiningArticle ER-00013107246 $123 $123 $add TO cart IN cart -

BASIC MILLING PACKAGEIdle speed adjustmentPerforming G-Code backwardsContinuation of the G-Code from the middle of the trajectory (frame)G-Code runtime calculationCreate and edit macrosArticle ER-00013109169 $85 $85 $add TO cart IN cart

BASIC MILLING PACKAGEIdle speed adjustmentPerforming G-Code backwardsContinuation of the G-Code from the middle of the trajectory (frame)G-Code runtime calculationCreate and edit macrosArticle ER-00013109169 $85 $85 $add TO cart IN cart -

NORMAL MILLING PACKAGEOne additional motorDrilling Cycle SupportIdle speed adjustmentCoordinate system rotation by G-codeQuick start G-Code from an arbitrary linePerforming G-Code backwardsContinuation of the G-Code from the middle of the trajectory (frame)G-Code runtime calculationBackground operationsCreate and edit macrosAuto Tool ChangeAutomatical spinle speed overridingArticle ER-00013108569 $285 $285 $add TO cart IN cart

NORMAL MILLING PACKAGEOne additional motorDrilling Cycle SupportIdle speed adjustmentCoordinate system rotation by G-codeQuick start G-Code from an arbitrary linePerforming G-Code backwardsContinuation of the G-Code from the middle of the trajectory (frame)G-Code runtime calculationBackground operationsCreate and edit macrosAuto Tool ChangeAutomatical spinle speed overridingArticle ER-00013108569 $285 $285 $add TO cart IN cart -

FULL MILLING PACKAGEDrilling Cycle SupportUnlimited motorsIdle speed adjustmentCoordinate system rotation by G-codePermission to use axes U, V and WQuick start G-Code from an arbitrary linePerforming G-Code backwardsContinuation of the G-Code from the middle of the trajectory (frame)G-Code runtime calculationOutput Control Commands M10/M11Background operationsCreate and edit macrosConnection of several Clients to one ServerAuto Tool ChangeAutomatical spinle speed overridingMulti-axis continuous machiningMODBUS protocol supportAnalog inputs supportDynamical motor to axis assignmentArticle ER-000161621092 $546 $546 $add TO cart IN cart

-

PLASMA BASEOne additional motorPlasma cutting server modeCreate and edit macrosArticle ER-00013111123 $62 $62 $add TO cart IN cart

PLASMA BASEOne additional motorPlasma cutting server modeCreate and edit macrosArticle ER-00013111123 $62 $62 $add TO cart IN cart -

PLASMA ADVANCEDPlasma cutting server modeUnlimited motorsIdle speed adjustmentCoordinate system rotation by G-codeQuick start G-Code from an arbitrary lineContinuation of the G-Code from the middle of the trajectory (frame)G-Code runtime calculationCreate and edit macrosLibrary of cutting parametersLock regulationSmart start from the middleIgnoring Z and F commands from G-CodeArticle ER-00013112538 $269 $269 $add TO cart IN cart

PLASMA ADVANCEDPlasma cutting server modeUnlimited motorsIdle speed adjustmentCoordinate system rotation by G-codeQuick start G-Code from an arbitrary lineContinuation of the G-Code from the middle of the trajectory (frame)G-Code runtime calculationCreate and edit macrosLibrary of cutting parametersLock regulationSmart start from the middleIgnoring Z and F commands from G-CodeArticle ER-00013112538 $269 $269 $add TO cart IN cart -

PLASMA FULLPlasma cutting server modeUnlimited motorsIdle speed adjustmentCoordinate system rotation by G-codeQuick start G-Code from an arbitrary linePerforming G-Code backwardsContinuation of the G-Code from the middle of the trajectory (frame)G-Code runtime calculationCreate and edit macrosLibrary of cutting parametersSmart Burn optionPerfect Hole OptionLock regulationProbing radiusBiphasic probingNesting simulationSmart start from the middleIgnoring Z and F commands from G-CodeArticle ER-00013113538 $269 $269 $add TO cart IN cart

PLASMA FULLPlasma cutting server modeUnlimited motorsIdle speed adjustmentCoordinate system rotation by G-codeQuick start G-Code from an arbitrary linePerforming G-Code backwardsContinuation of the G-Code from the middle of the trajectory (frame)G-Code runtime calculationCreate and edit macrosLibrary of cutting parametersSmart Burn optionPerfect Hole OptionLock regulationProbing radiusBiphasic probingNesting simulationSmart start from the middleIgnoring Z and F commands from G-CodeArticle ER-00013113538 $269 $269 $add TO cart IN cart -

PLASMA-GASPlasma cutting server modeUnlimited motorsIdle speed adjustmentCoordinate system rotation by G-codeQuick start G-Code from an arbitrary linePerforming G-Code backwardsContinuation of the G-Code from the middle of the trajectory (frame)G-Code runtime calculationCreate and edit macrosLibrary of cutting parametersSmart Burn optionPerfect Hole OptionLock regulationProbing radiusBiphasic probingNesting simulationSmart start from the middleIgnoring Z and F commands from G-CodeDynamical motor to axis assignmentArticle ER-000131141462 $731 $731 $add TO cart IN cart

PLASMA-GASPlasma cutting server modeUnlimited motorsIdle speed adjustmentCoordinate system rotation by G-codeQuick start G-Code from an arbitrary linePerforming G-Code backwardsContinuation of the G-Code from the middle of the trajectory (frame)G-Code runtime calculationCreate and edit macrosLibrary of cutting parametersSmart Burn optionPerfect Hole OptionLock regulationProbing radiusBiphasic probingNesting simulationSmart start from the middleIgnoring Z and F commands from G-CodeDynamical motor to axis assignmentArticle ER-000131141462 $731 $731 $add TO cart IN cart -

THERMAL FULLPlasma cutting server modeOxy-fuel cutting server modeUnlimited motorsCoordinate system rotation by G-codePermission to use axes U, V and WQuick start G-Code from an arbitrary linePerforming G-Code backwardsContinuation of the G-Code from the middle of the trajectory (frame)G-Code runtime calculationOutput Control Commands M10/M11Background operationsCreate and edit macrosConnection of several Clients to one ServerLibrary of cutting parametersSmart Burn optionPerfect Hole OptionLock regulationProbing radiusBiphasic probingNesting simulationSmart start from the middleIgnoring Z and F commands from G-CodePipe cuttingMODBUS protocol supportAnalog inputs supportDynamical motor to axis assignmentAutomatic zoned down draft air table controlArticle ER-000161632277 $1138 $1138 $add TO cart IN cart

Electronics

-

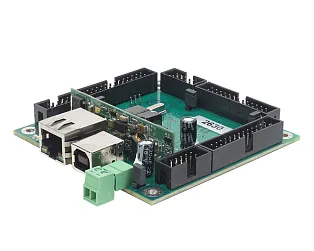

Ethernet controller PLCM-E3 is designed for connection to the CNC software Pumotix. Controller...

363 $add TO cart IN cart -

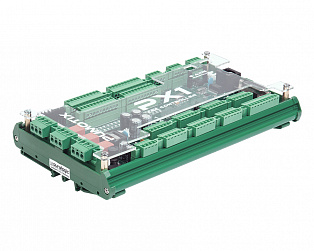

The PX series CNC motion controller is designed to create a multi-axis CNC system. The...

955 $add TO cart IN cart -

PoE Ethernet/USB controller PLCM-E3p (Ethernet power supply is possible) is designed for...

448 $add TO cart IN cart -

Ethernet controller PLCM-E4 is designed for connection to the CNC software Pumotix. Controller...

363 $add TO cart IN cart

-

CNC57R box is intented to control upto 4 axes of a CNC machine. It is equipped with 4 drivers...

1573 $add TO cart IN cart -

CNC57 box is intented to control upto 4 axes of a CNC machine. It is equipped with 4 drivers...

1818 $add TO cart IN cart -

CNC86-E4-2R2.2 box is itented to control upto 4 axes of a CNC machine and a spindle electromotor....

2812 $add TO cart IN cart -

CNC86-E6-2R2.2 box is itented to control upto 6 axes of a CNC machine and a spindle electromotor....

3477 $add TO cart IN cart -

CNC86-E6-2R4 box is itented to control upto 6 axes of a CNC machine and a spindle electromotor....

3827 $add TO cart IN cart -

CNC86-E4-2P1 box is itented to control upto 4 axes and a plasma cutter. It is compatible...

2917 $add TO cart IN cart -

Control cabinet CNC110-MR2.2 is intended to control a milling CNC machine. It consists ...

5083 $add TO cart IN cart -

Control cabinet CNC110-MR4.0 is intended to control a milling CNC machine. It consists ...

5162 $add TO cart IN cart -

Control cabinet CNC110-MR7.5 is intended to control a milling CNC machine. It consists ...

5347 $add TO cart IN cart -

Control cabinet CNC110-MP intended to control a plasma CNC machine. It consists of 3 drivers...

5030 $add TO cart IN cart

-

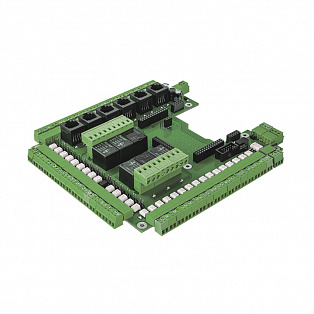

PLCM-B1-G2 is a expansion board for CNC Ethernet/USB PLCM controller. It allows to involve...

325 $add TO cart IN cart -

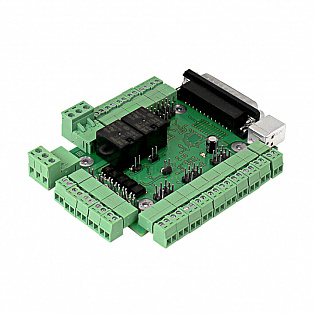

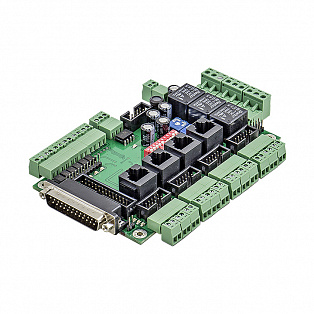

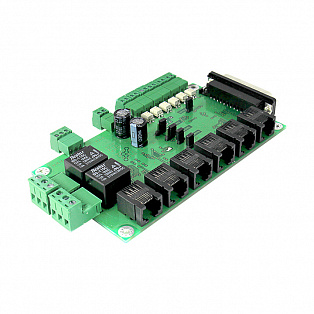

PLC5x is a breakout board, which allows to convert the personal computer (PC) into a full-fledged...

70 $add TO cart IN cart -

PLC4x-G2 is a breakout board, which allows to convert the personal computer (PC) into a...

182 $add TO cart IN cart -

PLCS6x is a breakout board, which allows to convert a personal computer (PC) into a full-fledged...

187 $add TO cart IN cart -

PLC6x-G2 is a breakout board, which allows to convert the personal computer (PC) into a...

139 $add TO cart IN cart -

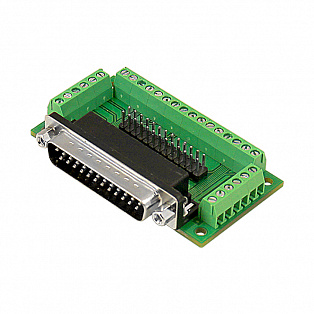

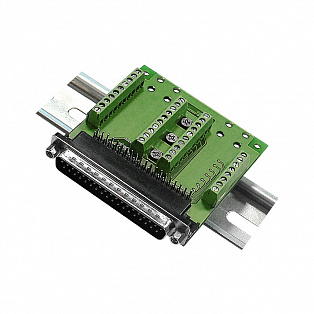

Connector PLB-DB25M is a BOB with DB25M plug for connecting equipment without soldering...

25 $add TO cart IN cart -

Connector PLB-DRB37M is a BOB with DRB37M plug for connecting equipment without soldering...

12 $add TO cart IN cart

-

PLC1Xi is an autonomous programmable motion controller (PLC). The controller is intended...

232 $add TO cart IN cart -

Control panel is used for remote control of CNC machine. Control panel is compatible with...

162 $add TO cart IN cart -

Height tool search sensor PLTLS is intended to be fixed on procedured material to find ...

38 $add TO cart IN cart -

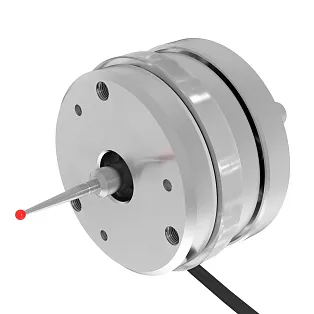

Contact sensor PLL005-G2 is manufactured for making measures before mechanical milling,...

164 $add TO cart IN cart -

Contact sensor PLL005-G3 is manufactured for making measures before mechanical milling,...

164 $add TO cart IN cart -

Contact sensor PLL006 is intended to make measures before mechanical milling, position ...

277 $add TO cart IN cart

-

The PLL-R2 set is designed for metal workpiece surface search in CNC plasma cutting devices....

205 $add TO cart IN cart -

The THC1 set is designed for automatic control of cutting height in plasma cutting devices....

700 $add TO cart IN cart -

The THC3 stand-alone controller is designed to control the cutting height in CNC plasma...

469 $add TO cart IN cart

-

PLDS880-L4 is a multichannel digital SM and SSM driver, based on signal DSP processor, ...

1196 $add TO cart IN cart -

PLDS880 is a DSP processor based on digital driver of Servo-Step Motor (SSM) with possibility...

262 $add TO cart IN cart -

PLD545-G4 is a DSP processor based digital driver of Stepper Motor with possibility of ...

228 $add TO cart IN cart -

PLD1090S is a DSP processor based digital driver of Servo-Step Motor (SSM) with possibility...

431 $add TO cart IN cart -

PLD880-G2 is a DSP processor based digital driver of Stepper Motor with possibility of ...

301 $add TO cart IN cart -

PLD8220-G3 is a digital new generation driver, manufactured to control stepper motors of...

514 $add TO cart IN cart -

Driver PLD880i is a modern and simple microstep driver with a built stepper motor controller....

196 $add TO cart IN cart

Options CAM-system

The entire functionality of the PUMOTIX CAM system is divided into several blocks by hardware type. As a matter of convenience, each block consists of separate independent options.

Package options CAM-system

-

THERMAL CUTTING (LEVEL 1)Extended built-in library of standard partsMultiple drawings supportTorch protection during piercingArticle ER-0001768866 $add TO cart IN cart

-

THERMAL CUTTING (LEVEL 2)Simple auto nestingUnlimited number of drawings per jobExtended built-in library of standard partsMultiple drawings supportTorch protection during piercingArticle ER-00017689134 $add TO cart IN cart

Our partner

About company

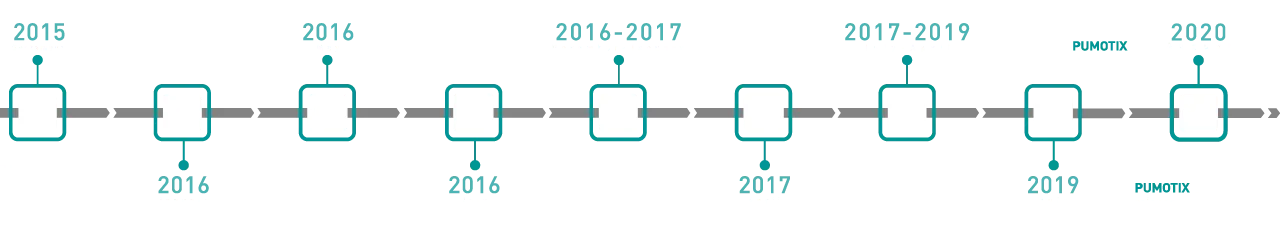

Purelogic R&D has always sought to improve its products and create a quality turnkey product: to supply not only components and machines, but also software for their full operation. That is why in 2016, the company's engineers have developed on the basis of the plcm series motion controller own hardware and software complex PureMotion (translated from English "clean motion"), which is well established in the CNC market.

With the growth of the customer base and applications for the development of new functionality, the company's management decided to create a new generation of software. In 2019, Purelogic R&D engineers started to develop a new hardware and software complex PUMOTIX. PUMOTIX has all the advantages of PureMotion and has a flexible licensing system. Now every purelogic R&D client has the opportunity to try out individual functions for free and buy the necessary software package for specific tasks, which can significantly save money.

There are different types of software systems to control CNC machines. The most popular of them are Puremotion (PUMOTIX), Mach3, Mach4, NCStudio, LinuxCNC, UCCNC, etc. The programs support various types of CNC machines (milling and engraving, plasma, laser and gas cutting, 3d printers, etc.) and differ in user interface and capabilities.

One of the most popular CNC software is Mach3. The package is used to work on milling, engraving and turning machines, equipment for laser and plasma cutting, and allows to produce quite complex work-pieces. There is a lot of literature and training videos about Mach3 functionality which provides with a possibility to learn the software features very quickly. Mach3 has a macros system (M-codes), based on the use of VBScript, that allows to expand processing capabilities significantly. However, there are some disadvantages of Mach3:

• software generation of STEP/DIR/ENABLE signals are processed on the output pins of the LPT port. That limits hardware support FOR older PCs and prevents laptops from being used to control a machine;

• Mach3 manufacturer no longer supports This SOFTWARE version;

• known "hang" problems of the program at execution of volume control programs.

The new version of Newfangled Solutions (Mach3 developer) is Mach4. The program excels in high speed and stability of performing holographic G-code. However, the licensed Mach4 software imposes quite high requirements to hardware.

LinuxCNC software is compatible only with Linux operating system. It has advanced functionality and is absolutely free. (The only disadvantage of the software is that it's too complicated to install for beginners.

Developing PUMOTIX, the developers took into account the strengths of existing products on the market. With their efforts, it was possible to avoid restrictions on connecting with modern computer equipment (including laptops) and to provide fast and qualitative performance of volume tasks. PUMOTIX has an intuitive English interface, does not require a user to have mandatory knowledge in programming sphere and guarantees reliable operation of a machine.

.jpg)

(1).jpg)